Common problems and solutions when using glitter vinyl transfer film

Common problems and solutions when using glitter vinyl transfer film include:

1. Uneven heat transfer machine platform: This can lead to uneven temperature and pressure during the transfer process, affecting the melting and curing of the hot melt adhesive. The solution is to adjust the heat transfer machine platform to a suitable level position.

2. Uneven fabric: Uneven temperature and pressure during fabric transfer can affect the melting and curing of the hot melt adhesive. The solution is to press the fabric flat before transferring.

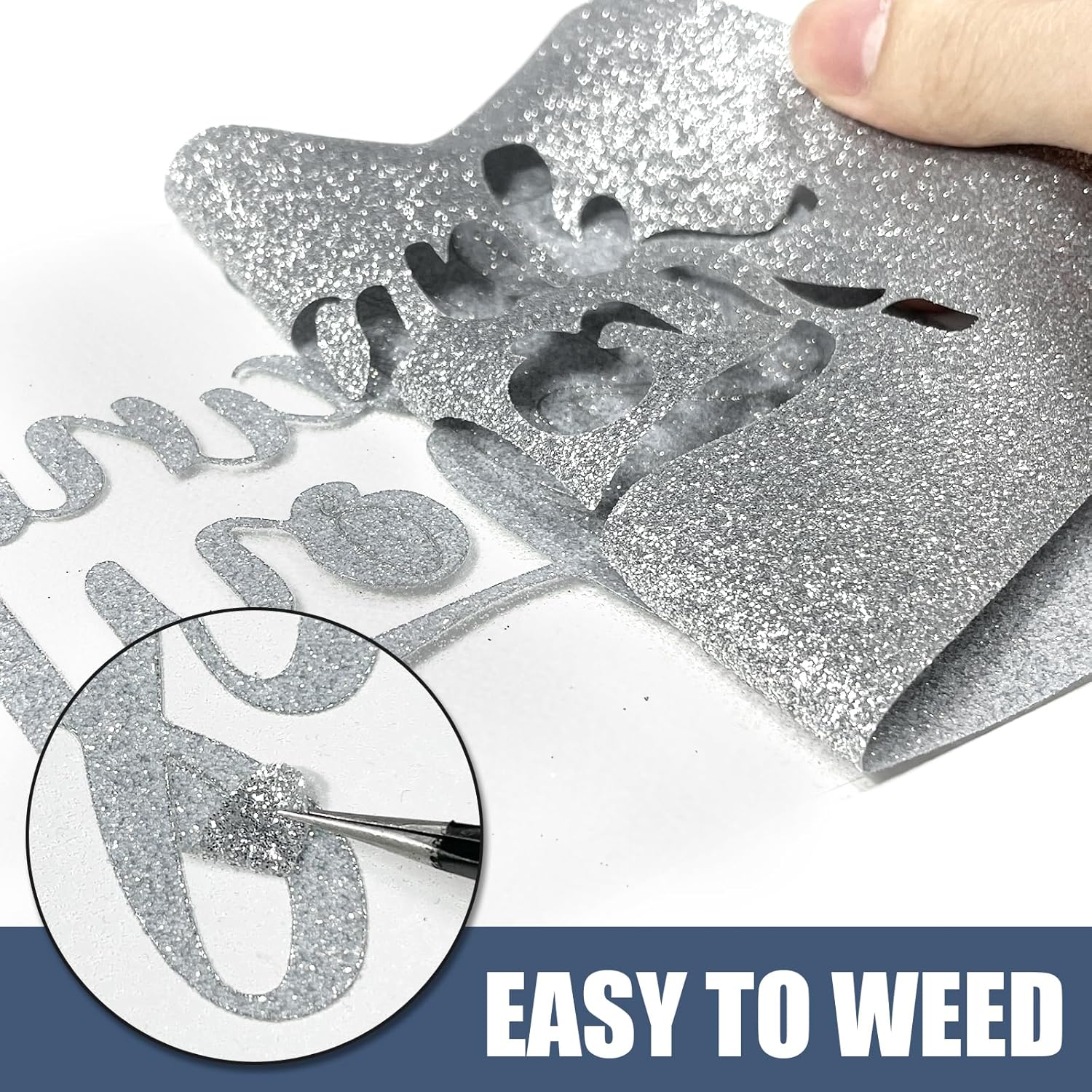

3. Too small patterns or too thin lines: The hot melt adhesive may have already melted during the engraving process. The solution is to avoid using transfer film for patterns or lines that are less than 0.5mm.

4. Waterproof fabric issues like down jacket fabrics: These fabrics have a silicone oil waterproof layer that requires a specific waterproof fabric adhesive.

5. Hot tearing after transfer: Hot tearing can cause the adhesive to not set properly, leading to poor adhesion. The solution is to cold tear the transfer film, waiting about 8 minutes before peeling off.

6. Washing test immediately after transfer: It is necessary to wait for 24 hours before conducting a washing test.

7. Insufficient pressure from the heat transfer machine: Test the pressure manually by placing a release film on the press plate and trying to pull the release film. If it moves, the pressure setting of the heat transfer machine is not enough and needs to be reset.

8. Insufficient transfer temperature: Test with a temperature gun. If a layer of fabric is added on the press plate, it is recommended to increase the transfer temperature by about 10-20 degrees.

9. Moisture in the fabric: Moisture can affect the transfer temperature and pressure, impacting the melting and curing of the hot melt adhesive. The solution is to press for more than 5 seconds to evaporate the moisture on the fabric before transferring.

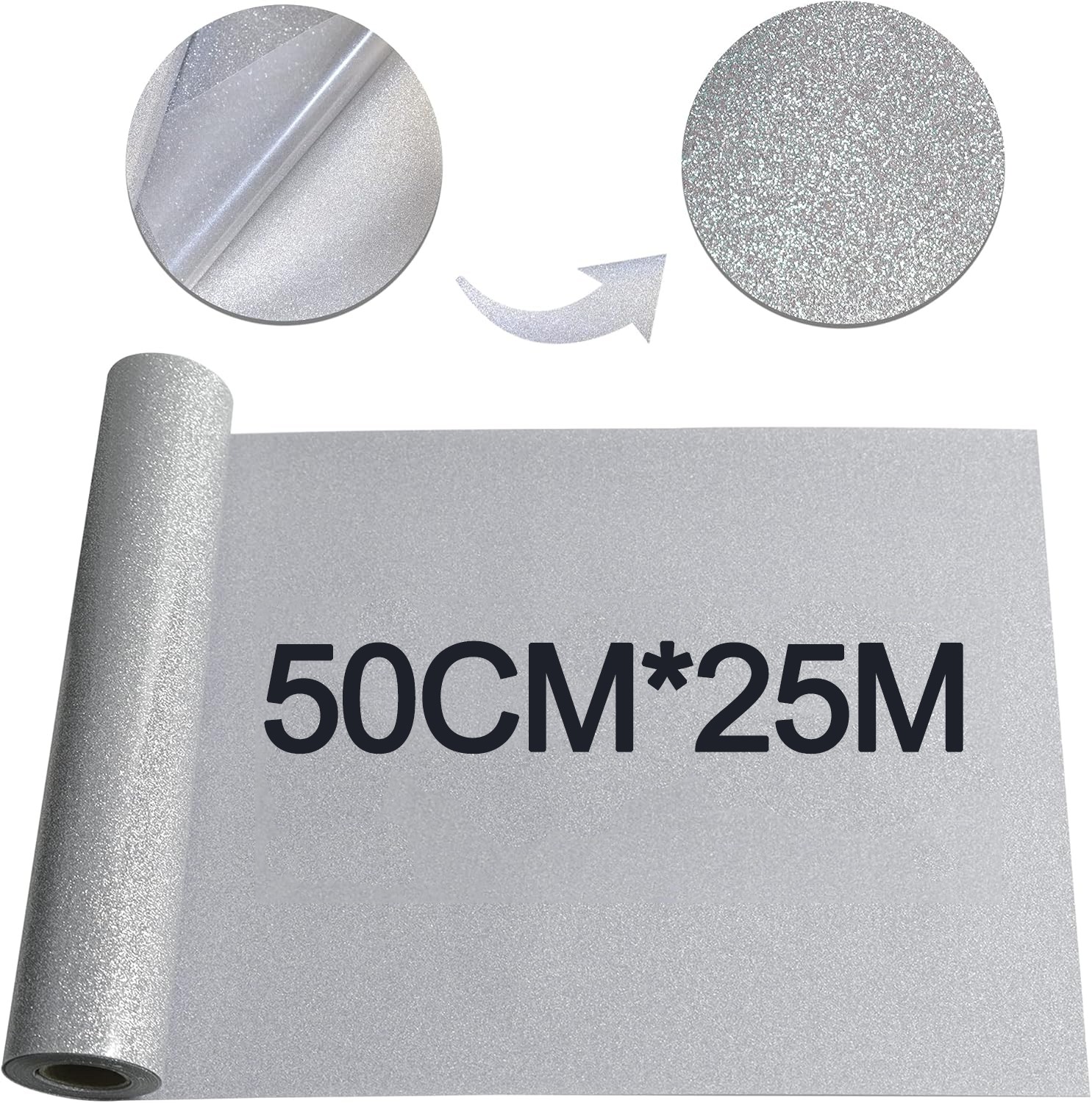

10. Storage of glitter vinyl transfer film: Store in a cool, dry place, avoid sharp objects, and seal any unused portions to prevent moisture and high temperatures.

11. Not testing a small sample before mass production: This can lead to quality issues in large-scale production. The solution is to test a small sample before mass production to ensure quality.

When using glitter vinyl transfer film, it is also important to use the correct transfer temperature and time, as well as the correct methods for transferring and peeling, to ensure the quality and effect of the final product.

上一篇:温变热转印刻字膜

刻字膜

刻字膜是一种广泛应用于服装、皮革印刷的热转印烫画材料。这也是艳燕公司主推的优势产品。

其转印原理是,刻字膜的材料带有胶黏剂,在热与压力的共同作用下,连同离型层一起脱离载体薄膜,牢固转印在承印物表面的特殊功能。

刻字膜表面是一层膜,但这一层膜,一般由3~5层构成,三层热转印膜由基底层、印刷层和胶黏层构成;四层热转印膜由基底层、离型层、印刷层和胶黏层构成;五层热转印膜由基底层、离型层、印刷层、胶黏层和热熔胶粉层构成。每一层有不同的效果和功能。

所以,表面看上去差不多的刻字膜,但用料上可能不同,好的刻字膜,还要要看“内功”。

热转印刻字膜是艳燕的主推核心优势产品,艳燕在热转印刻字膜拥有同行不可比拟的优势,首先是生产材料的选择上,我们选择高品质环保的材料,确保产品使用的安全。

其次是在生产控制上,我们拥有先进的设备,一流的生产技术人员,能更好的管控热转印刻字膜的生产质量,产品品质更高。

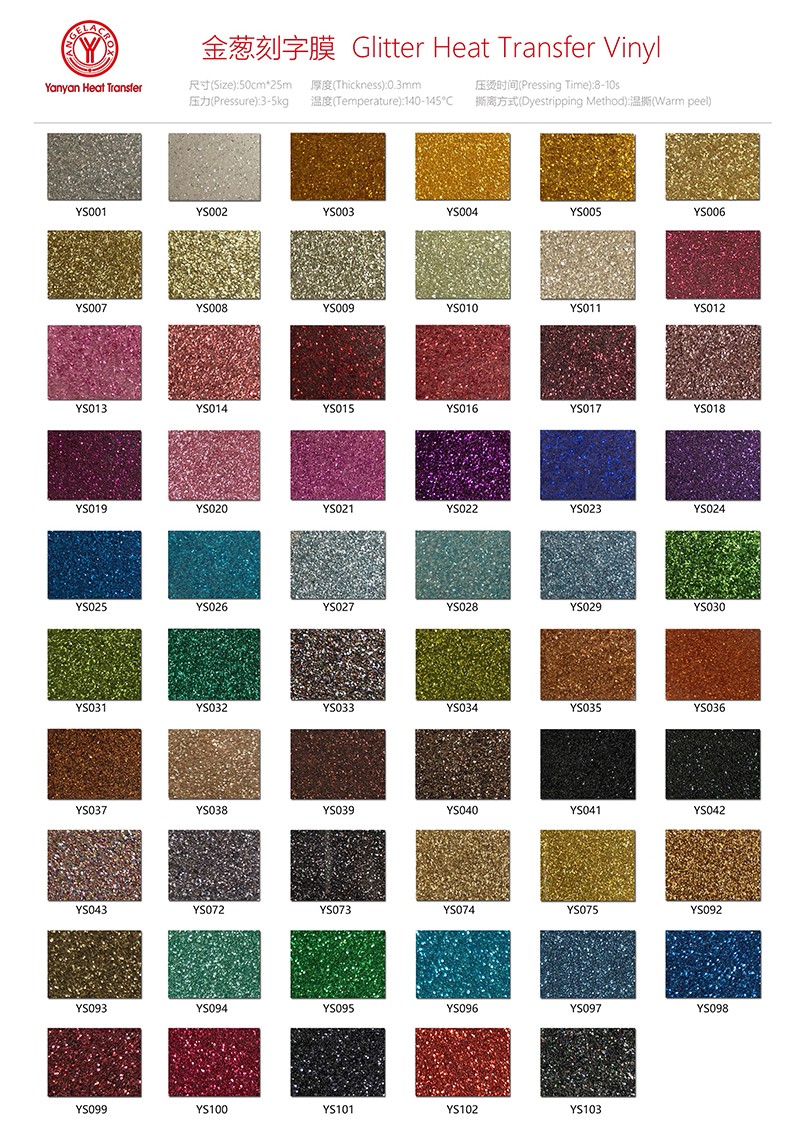

本公司拥有各类刻字膜产品,如PU刻字膜,PVC刻字膜,PET金属刻字膜,金葱刻字膜,反光刻字膜,烫金刻字膜,植绒刻字膜,硅胶刻字膜,纹路刻字膜,夜光刻字膜等,此外还有水转印、3D真空花膜、3D幻彩标等相关产品。